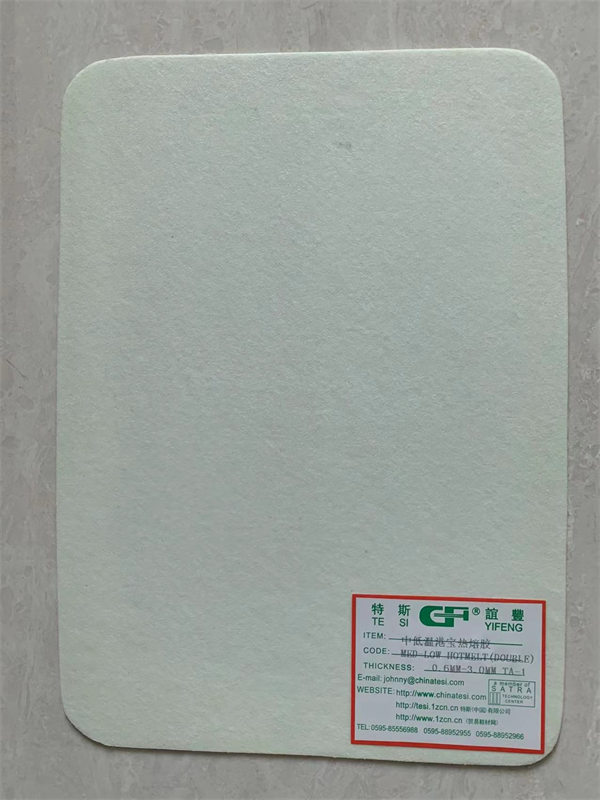

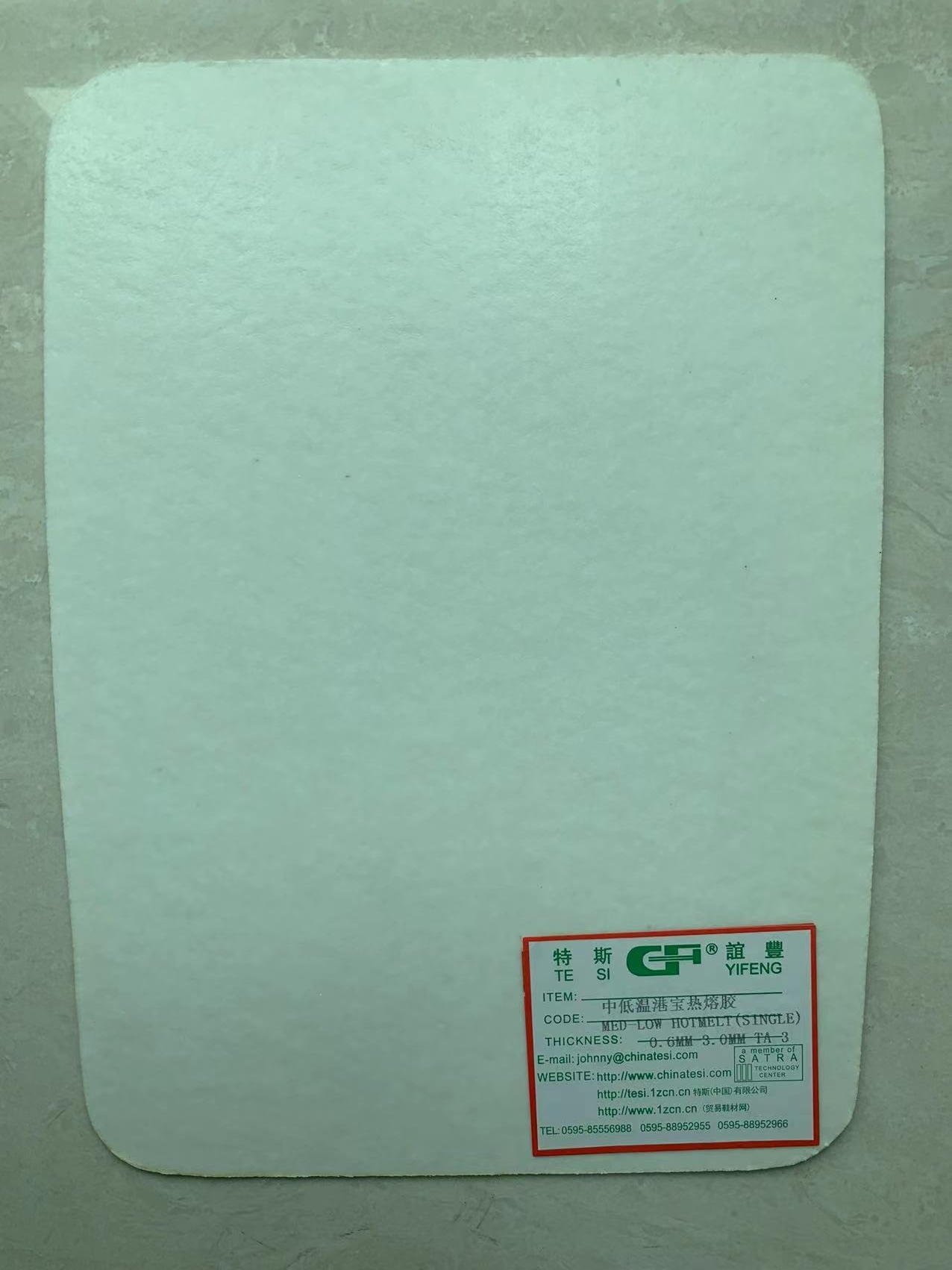

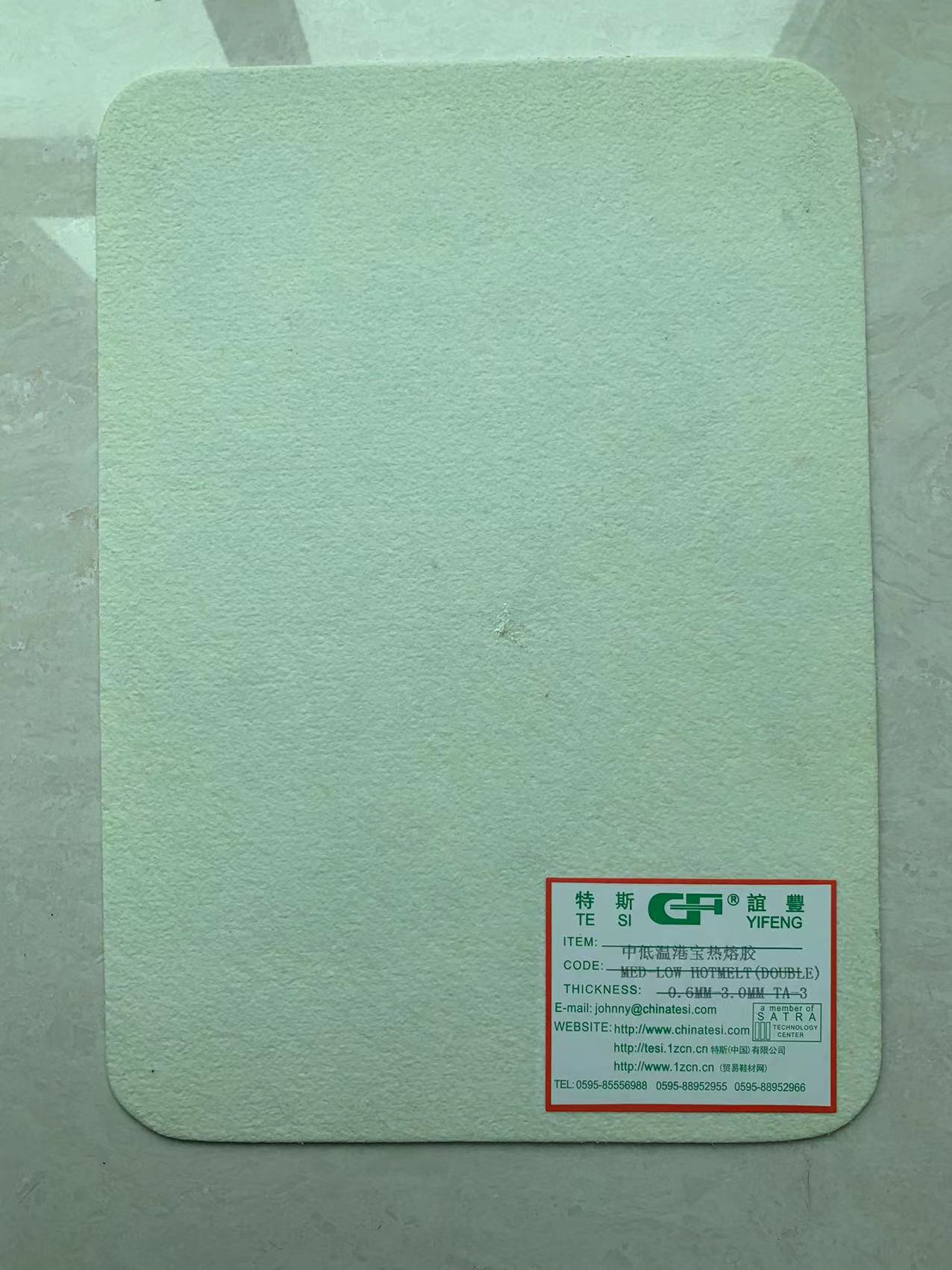

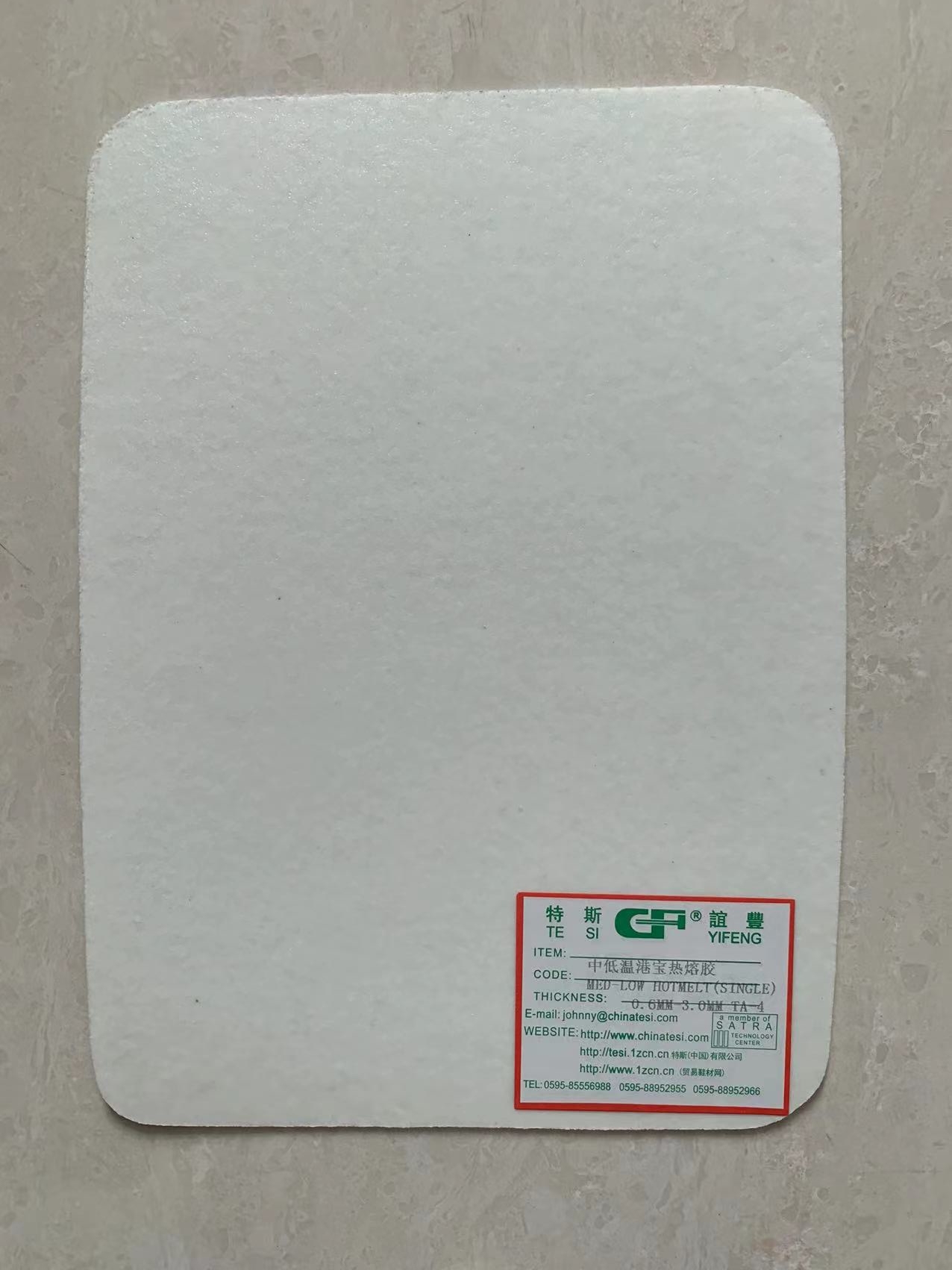

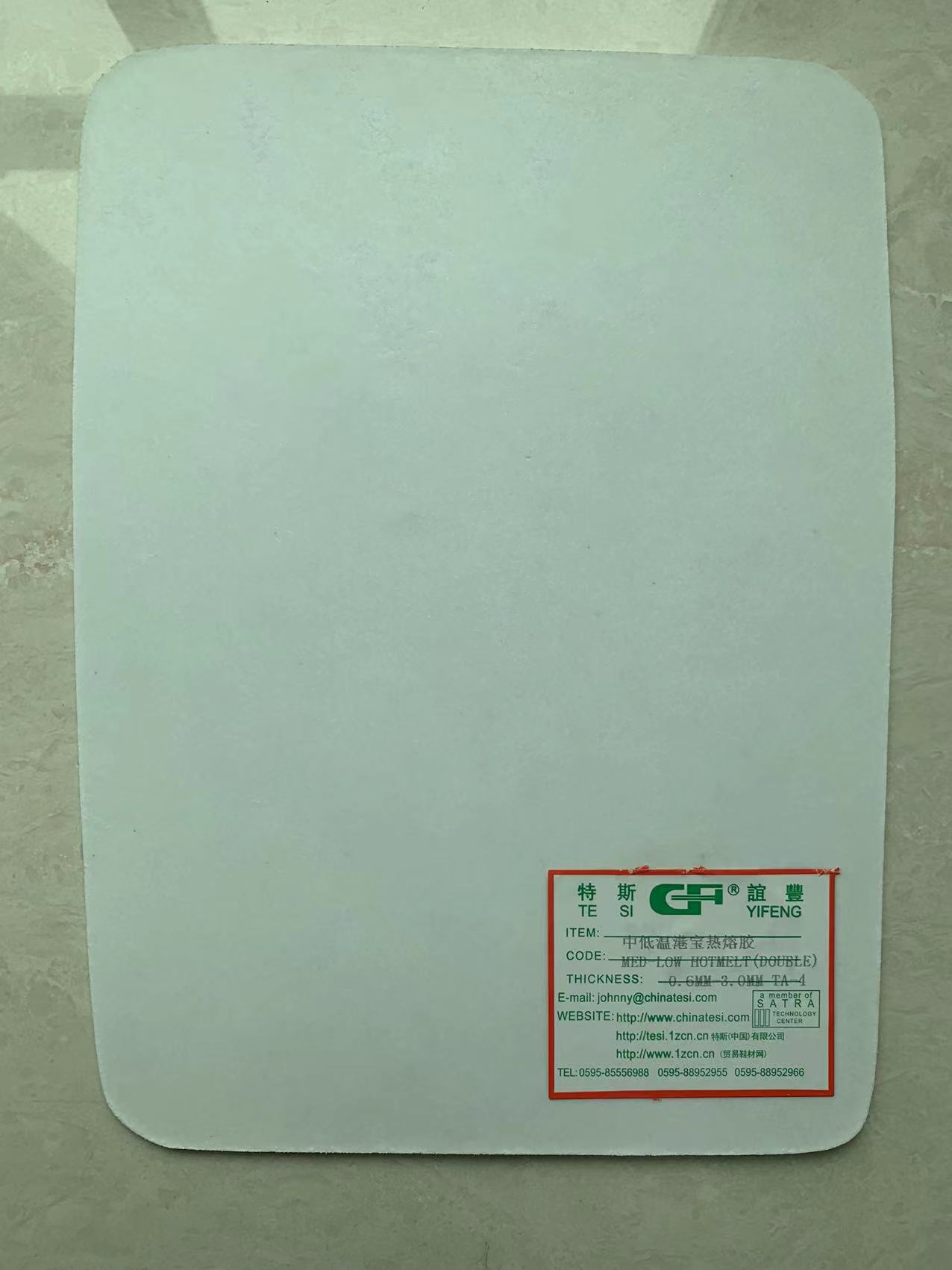

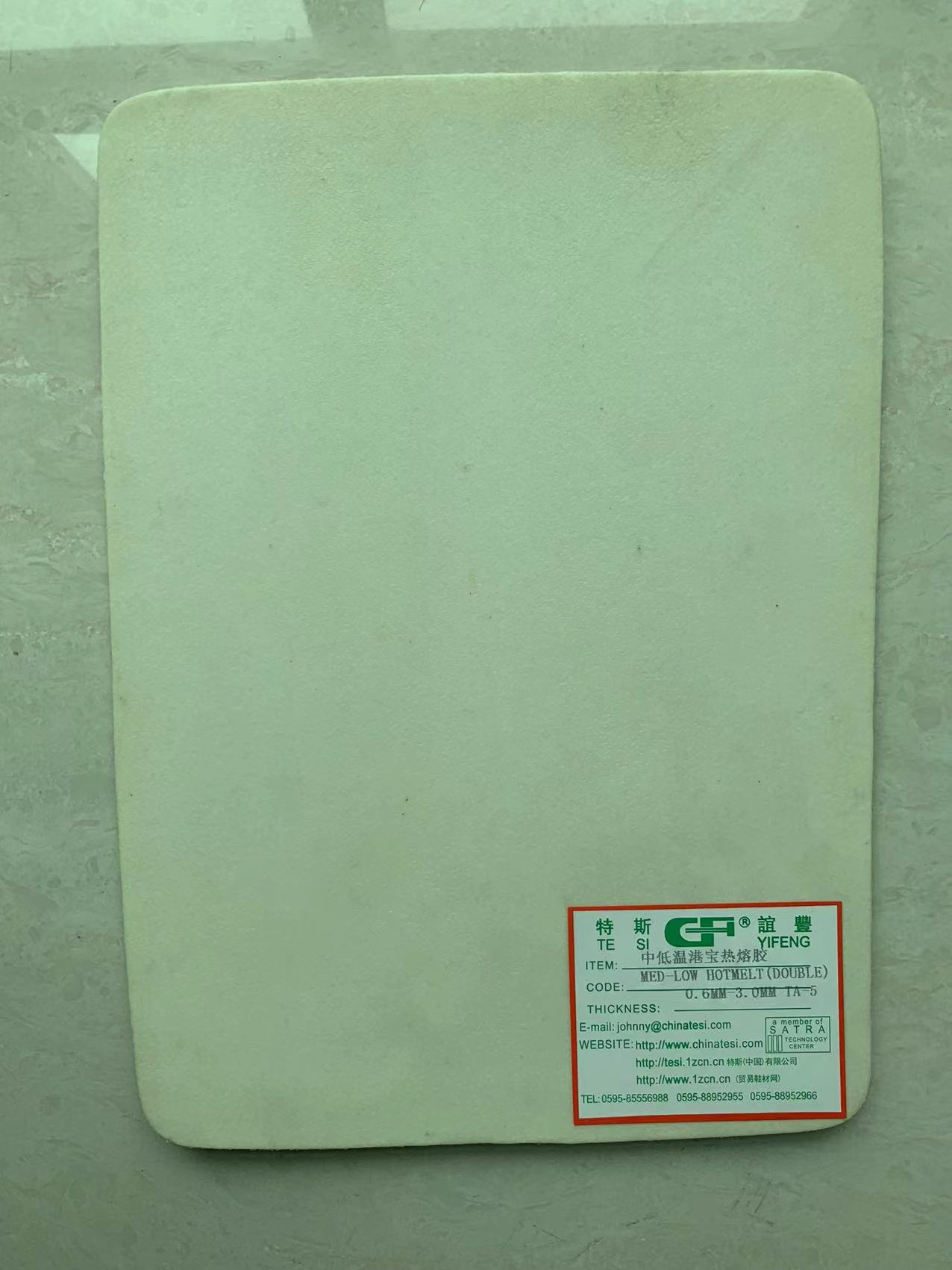

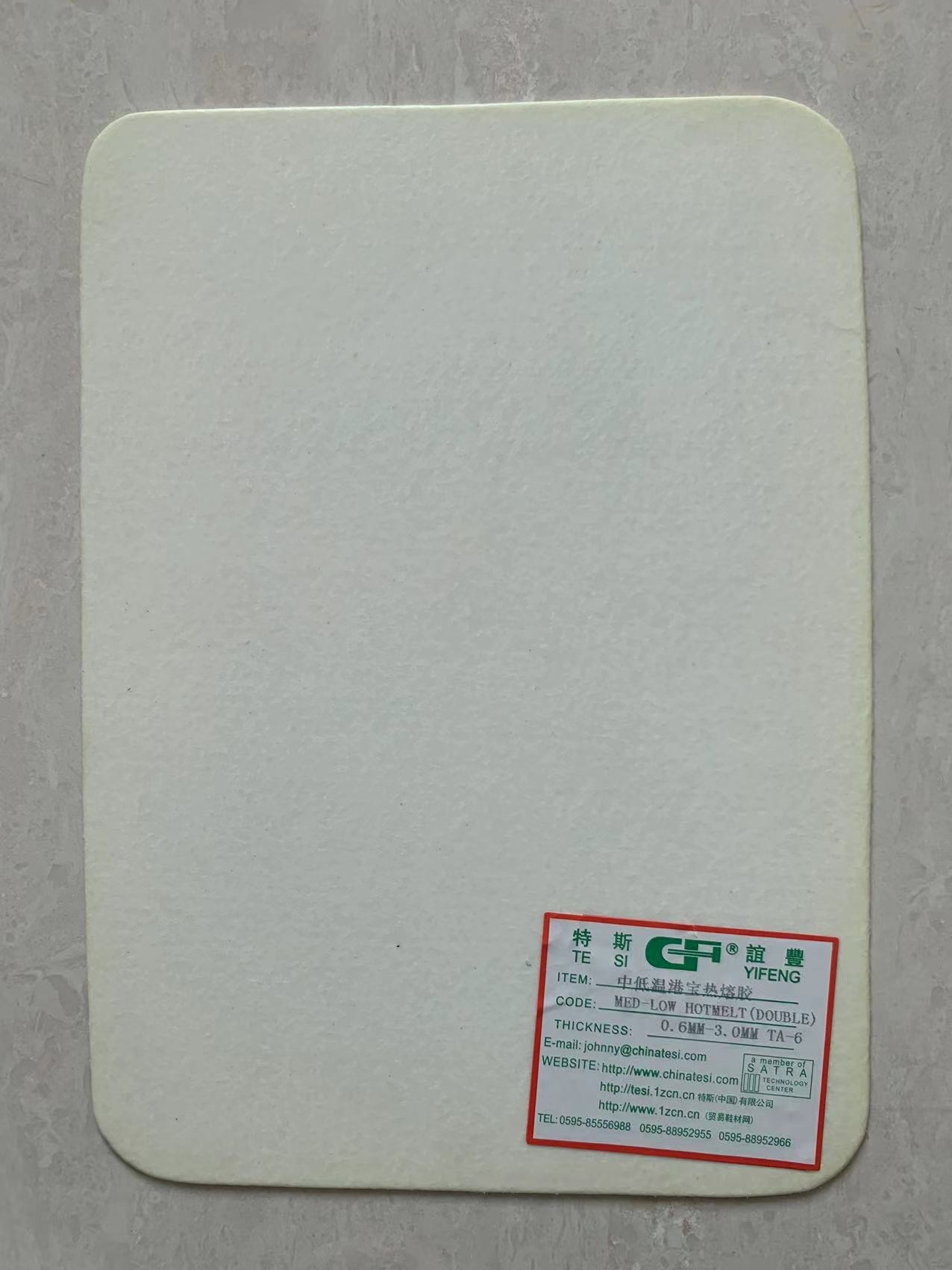

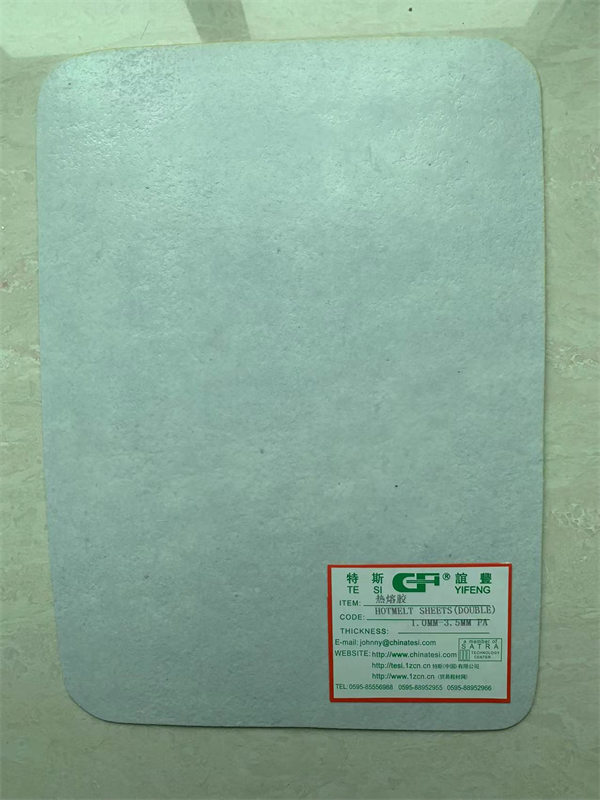

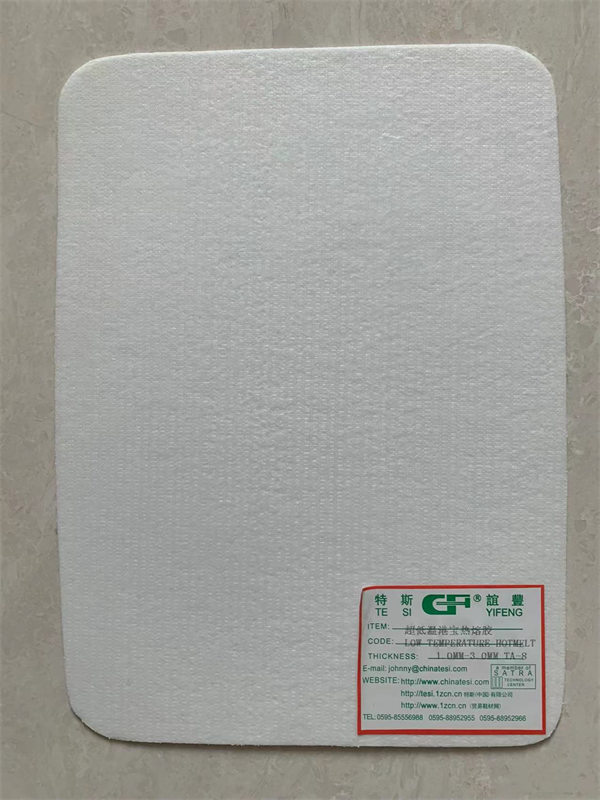

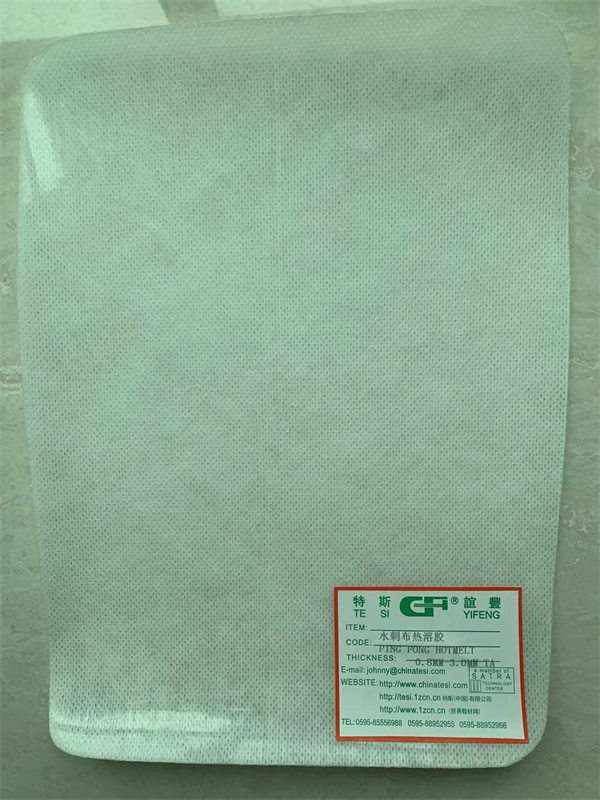

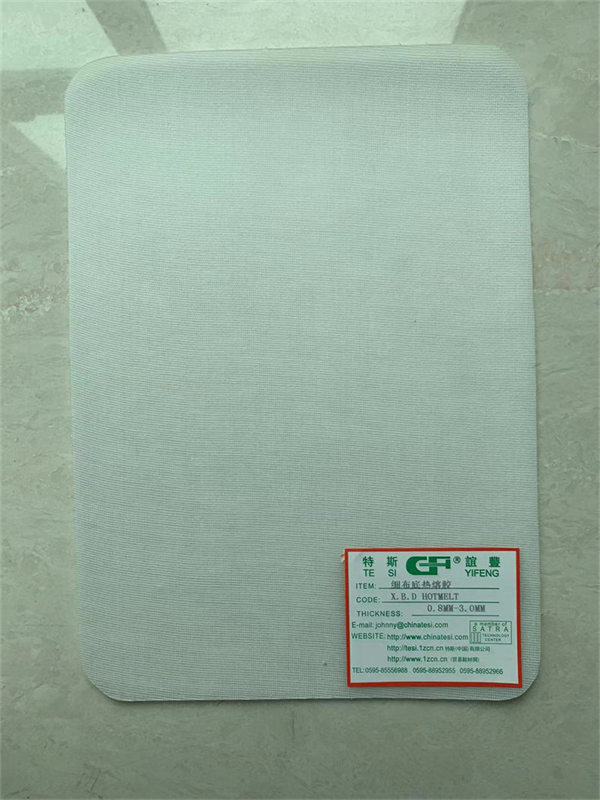

Mid Temperature Hotmelt Sheet

Brand TESI(CHINA).,CO LTD

Product origin Fujian

Delivery time 10 ~ 15 days

Supply capacity 50000-100000 tablets a day

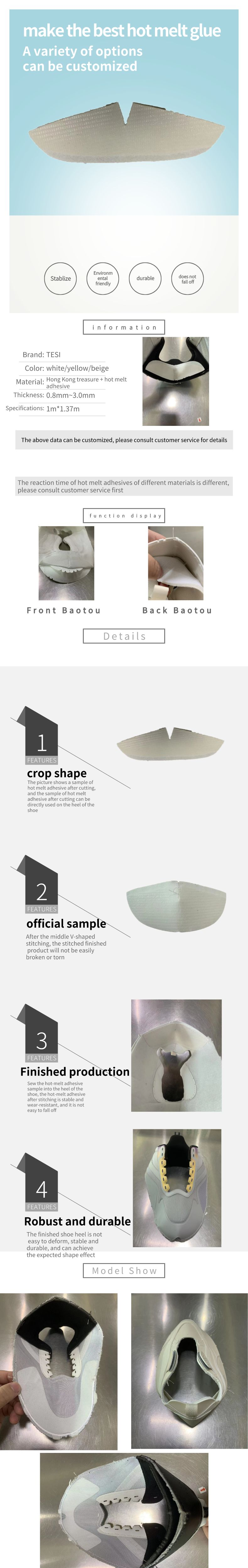

The main application range of medium and low temperature hot melt adhesives is the forefoot and heel of shoes. After the medium and low temperature hot melt adhesive is set, the material has memory elasticity, waterproof, non-deformation, fast bonding and good viscosity. The medium and low temperature hot melt adhesives produced by our company are TA1, TA3, TA4, TA5, TA6. Melting point is 120° - 150°. The reaction speed of medium and low temperature hot melt adhesives is generally within 15 seconds, and the fast bonding is not easy to crack and firm.

The main application of medium and low temperature hot melt adhesives is at a temperature of 120~150 degrees, which can be easily applied to materials with different tolerance levels. We also have ordinary temperature hot melt adhesives and ultra-low temperature hot melt adhesives for customers to choose.

The melting point of medium and low temperature hot melt adhesives is about 120° to 150 degrees, and most of them are used in toe caps and heels. The surface of medium and low temperature hot melt adhesives produced by us is stable and free of impurities. There are many types of specifications and materials of different grades. have different uses.

The advantages of medium and low temperature hot melt adhesives are many, the hardness is stable, and the goods will not be half hard and half soft. The setting speed is fast, which can help customers get the effect they want faster. Good viscosity, will not fall off after heating temperature.